What is LED Display San Mode

What is led display scan mode

led display scan mode

Scan mode, also called Scan rate or scanning driving, refers to the number of LED pixels that can be connected to a single driver IC. Each pixel is connected to a pin on the driver IC on the PCB board. The number of drivers required on a PCB board design to illuminate the pixel pitch determines the scan type.

Two types of Scan modes:

1. Static scanning:

Static scanning is to implement “point-to-point” control from the output of the driver IC to the pixels.

2. Dynamic scanning:

Dynamic scanning is to implement “point-to-column” control from the output of the driver IC to the pixel points.

Several factors, including the type and performance of the driver IC, refresh rate, grayscale, and pixel pitch directly influence the scan design.

Table of Contents

- led display scan mode

- Two types of Scan modes:

- 1. Static scanning: 2. Dynamic scanning:

- Why is Dynamic driving mode essential?

- Scan Mode,brightness,refresh rate and grey level

Brightness

Power Consumption

Refresh Rate

A single driver IC has 16 pins output and can drive a maximum of 16 LED chips. In static drive mode, all LEDs on the LED module can be driven by the IC simultaneously, as illustrated in the following image.

Static: A single-driver IC has 16 pins and can drive a maximum of 16 LED chips. In static drive mode, all LEDs on the LED module can be driven by the IC simultaneously, as illustrated in the following image.

1/2 Scan: In 1/2 scan mode, the IC drives a set of 1/2 LEDs on the module at a time, and subsequently switches to another set of 1/2 LEDs.

1/4 scan: 1/4 of LEDs on the module are driven by IC at one time, and next time there are other 1/4 LEDs that are driven.

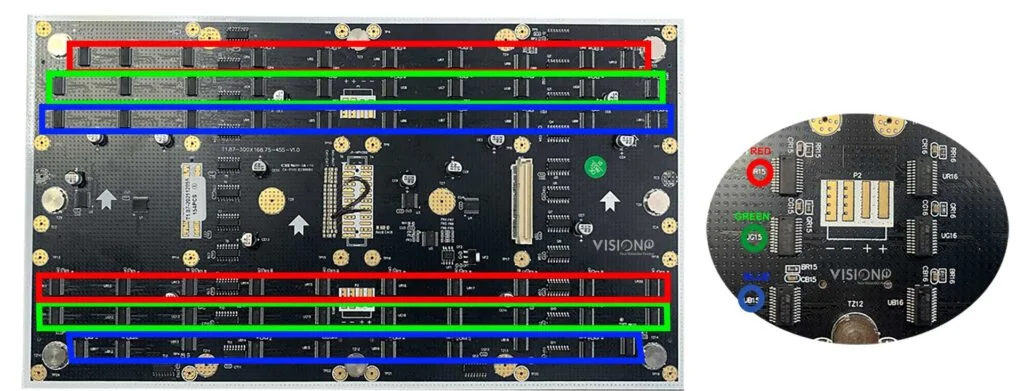

Taking a 1/45 scan P1.875 design with the LED and driver IC on the same side as an example:

Module size:300×168.75mm; pixel resolution: 160×90=14,400 dots.

Each LED contains 3 color chips(1R1G1B), so there is a total of 14,400×3=43,200 colors in one led module.

with 1/45 scan driving mode. only 43,200/45 =960 colors are required to be lit up each time.

Since each Driving IC has 16 pins. so the total amount of Driving ICs required for one module is 960/16 = 60 pcs (2o pcs for Red color;20 pcs for Green Color;20 pcs for Blue color)

Why is Dynamic driving mode essential?

A static driver design (P1.875) would require 2700 16-channel driver ICs and current setting resistors. That will lead to an increased number of PCB layers and costs, on the other hand, the brightness is much higher but the current is also too high.

A dynamic driving mode design utilizes a single driver IC to activate more LEDs, conserving space on the PCB board and optimizing the budget and driver IC’s layout. However, when aiming for high image quality, there is a trade-off between high grayscale and high scan rate. As a result, a smaller pitch necessitates more time-multiplexing in the design. Typically, P2.5 displays implement a 1:16 time-multiplexing design, whereas displays with a pitch of 2 mm and below require time-multiplexing above 1:16.

Scan Mode,brightness,refresh rate and grey level

The lower the scan rate, the better the performance and the more expensive it will be.

- BrightnessThe higher the scan the more LED pixels one driver needs to light at once. The brightness is doubled compared to a 1/2 scan, and with a 1/4 scan, the brightness doubles compared to a 1/8 scan. Nevertheless, adjusting the software through experimentation can reduce the brightness if high brightness is not essential. in some cases, the outdoor fine pixel pitch led display requires a super high brightness of 6000-10000nits, the high brightness gold wire LED can provide the required brightness in a lower scan mode (1/13scan 1/16 scan)

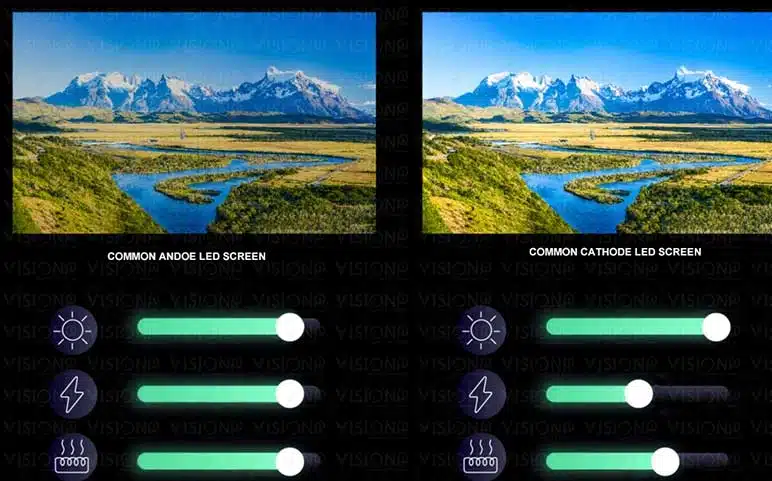

- Power Consumption Increasing the scan rate results in higher power consumption. A simple formula accurately reflects this correlation: for instance, a 1/8 scan consumes twice as much power as a 1/16 scan. The current is also a limiting factor. In the future, factories may reduce current, thereby diminishing both power consumption and brightness. commom cathode technolgy can reduce the power consumption without sacrifce the brightness.

- Refresh RateThe refresh rate of a screen is indicated in hertz (Hz) and signifies how frequently the image is updated per second. When the number of scan lines is doubled, the time required to illuminate all LEDs will increase twofold, and the refresh rate will be halved. Thus, increasing the number of time-multiplexing in a design makes it more challenging to achieve a high refresh rate. Decreasing the scan rate will reduce the refresh rate and vice versa. However, the PCB design and type of driver IC also influence the refresh rate. Incorporating a driver IC with an embedded SRAM can enhance the refresh rate by decreasing the time required to transmit grayscale data. If the driver IC supports GCLK multiplier technology, the refresh rate must be doubled.

Choosing a scan mode for LED display is a crucial decision that depends on various factors, such as brightness, power, refresh rate and cost. A higher scan mode is not always better, nor is a lower one. The goal is to design an optimal LED screen that meets the desired specifications.

Transparent LED Mesh Screen

Transparent LED Mesh Screen